Characteristic advantages

1. High conductivity : Conductivity of over 99%, suitable for EMI/RFI electromagnetic shielding|

2. Good ductility : Easy to form and bend|

3. Good corrosion resistance : Resistant to water, air, and some weak acid corrosion|

4. Non magnetic material :Suitable for precision electronic environments|

5. Antibacterial : It has a natural antibacterial effect and is suitable for certain medical or living scenarios|

Common specifications

Mesh Count (mesh/inch) | Wire Diameter (mm / inch) | Aperture Size (mm / inch) | Open Area (%) | Weave Type | Typical Applications |

4 × 4 | 0.80 mm / 0.0315" | 5.55 mm / 0.218" | ~74% | Plain Weave | Ventilation mesh, coarse filtering, decorative mesh |

6 × 6 | 0.55 mm / 0.0217" | 3.67 mm / 0.1445" | ~70% | Plain Weave | Insect screens, architectural mesh |

8 × 8 | 0.50 mm / 0.0197" | 2.68 mm / 0.1055" | ~67% | Plain Weave | Garden screens, EMI shielding (low frequency) |

10 × 10 | 0.50 mm / 0.0197" | 2.04 mm / 0.0803" | ~65% | Plain Weave | Grounding mesh, RFI shielding |

16 × 16 | 0.40 mm / 0.0157" | 1.19 mm / 0.0468" | ~58% | Plain Weave | Shielded enclosures, filter base layer |

20 × 20 | 0.35 mm / 0.0138" | 0.92 mm / 0.0362" | ~51% | Plain / Twill | Electromagnetic shielding, signal filtering |

30 × 30 | 0.25 mm / 0.0098" | 0.59 mm / 0.0232" | ~46% | Twill Weave | Conductive pads, insect screens |

40 × 40 | 0.20 mm / 0.0079" | 0.43 mm / 0.0169" | ~44% | Twill Weave | Audio shielding, lab testing enclosures |

60 × 60 | 0.15 mm / 0.0059" | 0.27 mm / 0.0106" | ~40% | Twill Weave | Fine EMI shielding, grounding in high-frequency devices |

80 × 80 | 0.12 mm / 0.0047" | 0.20 mm / 0.0079" | ~36% | Dutch Weave | Precision gas/liquid filtration, signal protection |

100 × 100 | 0.10 mm / 0.0039" | 0.15 mm / 0.0059" | ~30% | Dutch Weave | Microfiltration, electronics shielding |

120 × 120 | 0.08 mm / 0.0031" | 0.13 mm / 0.0051" | ~28% | Dutch Weave | EMI/RFI shielding mesh for sensitive components |

200 × 200 | 0.05 mm / 0.0020" | 0.077 mm / 0.0030" | ~25% | Dutch Weave | Electrolytic shielding, ultrafine filtration |

application area

EMI/RFI Shielding

Used in data centers, labs, and electronic equipment for electromagnetic interference shielding.

Electronics & Electrical Engineering

For conductive mesh, electrode mesh, and grounding mesh.

Filtration & Sieving

Applied in filtering gases, liquids, or particles, especially in conductive environments.

Decorative & Artistic Use

Ideal for interior decoration, crafts, and sculpture.

Chemical & Metallurgical Industry

As corrosion-resistant filters, catalyst support mesh, or drying materials.

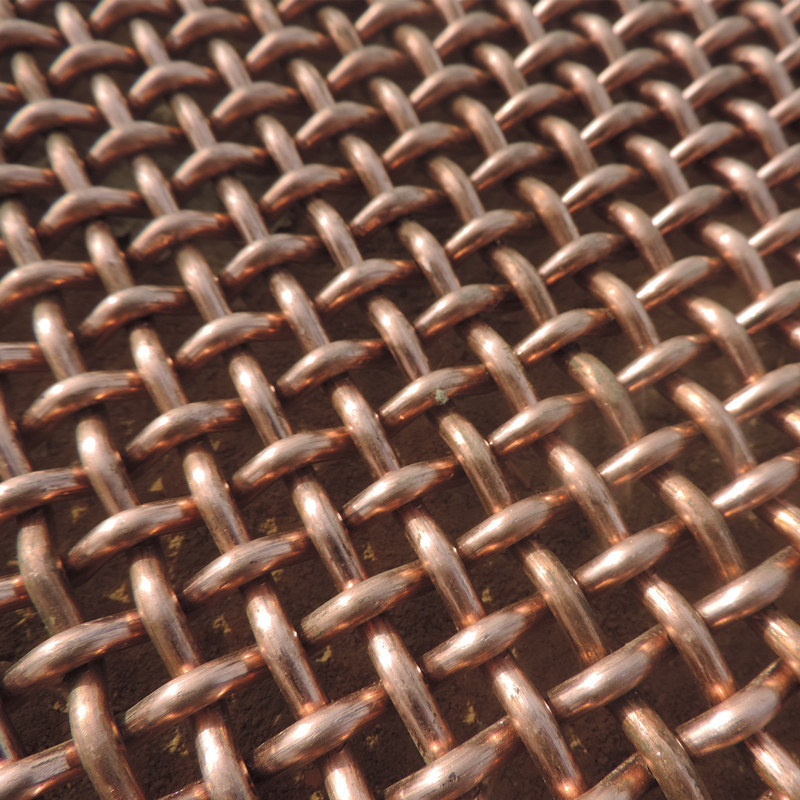

The Red Copper Woven Wire Mesh is a high-performance material crafted from pure red copper wires, known for its superior electrical and thermal conductivity. It is widely used in electronic shielding (EMI/RFI), signal grounding, and filtration systems, where conductivity and corrosion resistance are essential.

This mesh is woven in various patterns, including plain weave and twill weave, to suit different application needs. Its fine mesh openings make it suitable for precise particle separation in air, liquids, or gases. Moreover, the mesh is flexible yet strong, allowing it to be easily cut, bent, or shaped into various forms for equipment enclosures or filter housings.

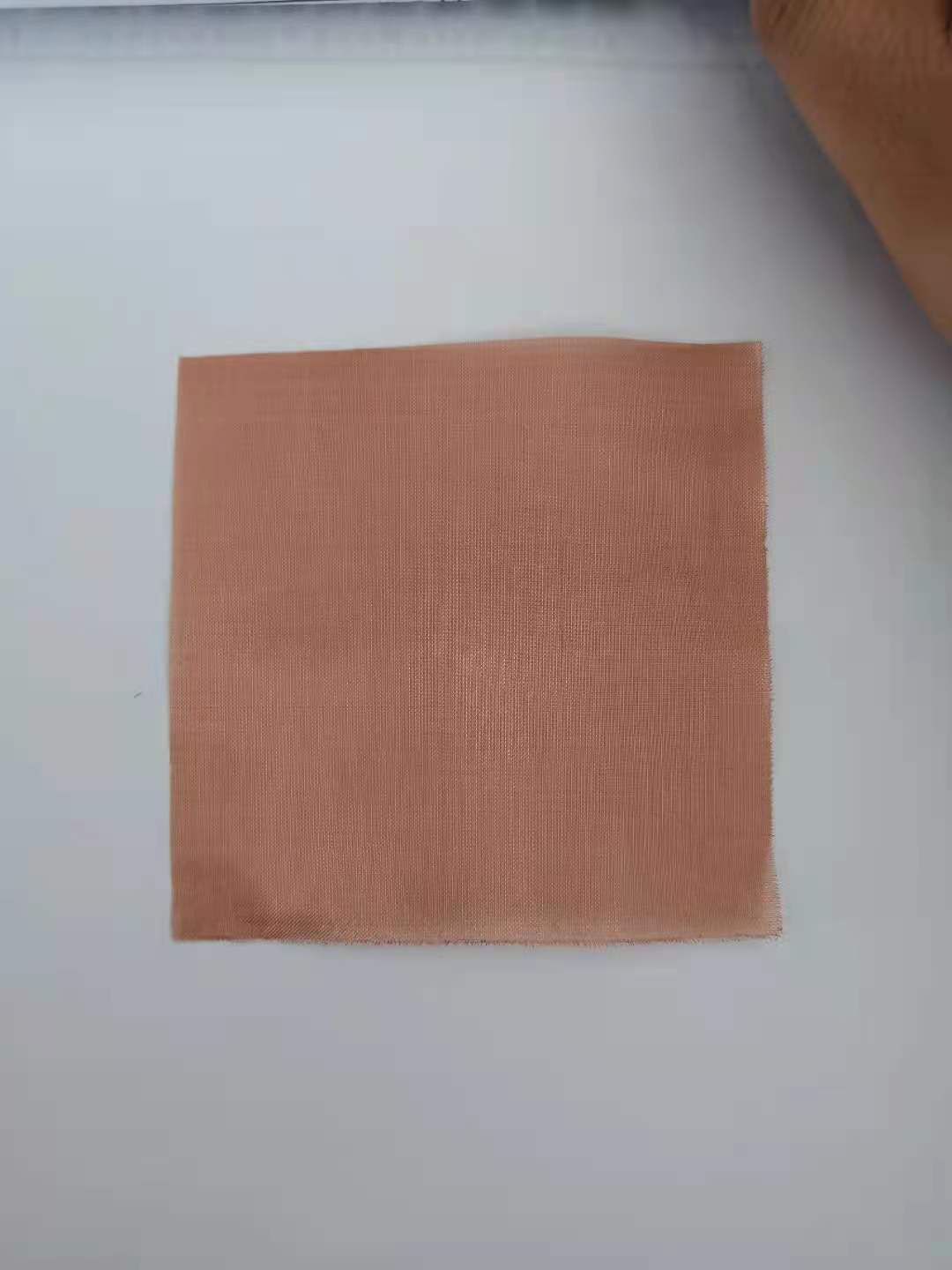

Because of its natural reddish color and lustrous finish, Red Copper Woven Wire Mesh is also popular in architectural and interior design. It can be used as decorative panels, lighting covers, or artistic installations while retaining its functional benefits such as ventilation or insect screening.

Additionally, copper’s antimicrobial properties make this mesh ideal for medical and food-grade applications where hygiene is critical. Available in a wide range of mesh counts, wire diameters, and roll or sheet sizes, our red copper mesh is both customizable and ready for immediate use in diverse industries.

Our Red Copper Woven Wire Mesh is manufactured using high-purity copper wire, offering excellent malleability, ductility, and oxidation resistance. Its unique blend of strength and flexibility makes it suitable for a wide range of uses across industrial, commercial, and decorative fields.

In industrial environments, red copper mesh serves as an effective filtration and separation medium, especially in chemical processing and oil filtration where resistance to weak acids and water corrosion is vital. Its conductive properties also make it an ideal material for electromagnetic shielding in electronics manufacturing and laboratory settings.

As a woven wire mesh, the interlocking copper wires provide structural integrity and uniform mesh openings. This ensures consistent performance whether the mesh is used for screening, ventilation, or as a support layer in composite filter assemblies.

In addition to industrial uses, this mesh is widely adopted in decorative and architectural applications due to its warm, eye-catching hue and natural metallic sheen. From cabinetry inserts and ceiling panels to modern sculpture and lighting designs, Red Copper Woven Wire Mesh blends functionality with visual appeal.

The mesh is easy to cut, fold, and weld, making it user-friendly for custom fabrication. With multiple mesh sizes and wire thicknesses available, it can be tailored to meet specific airflow, filtration, or design requirements. Whether you're shielding sensitive equipment or enhancing a visual space, this versatile mesh offers exceptional performance and aesthetics.

Please leave us a message and we will get back to you shortly.