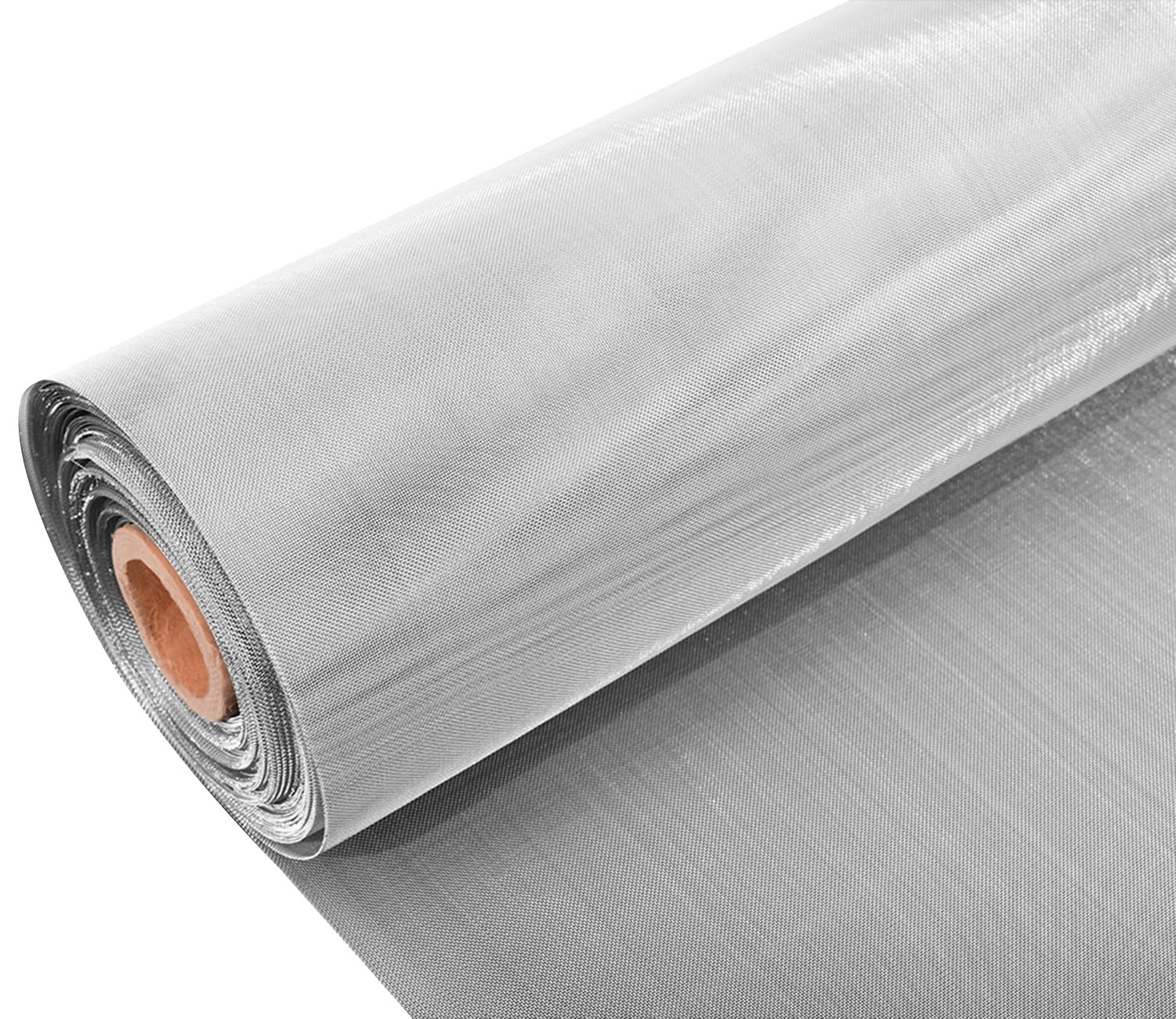

Characteristic advantages

Nickel woven wire mesh or low-alloy nickel woven wire mesh is useful in chemical processing because of its resistance to various chemicals including acid, alkali. It is also useful in the electronics due to its high electrical conductivity. The Nickel wire can be also used in the heat exchange due to its thermal conductivity and ductility.

Common specifications

Material: nickel 200, nickel 205, nickel 270, N2, N4, N6, N8.

Weaving type: plain weave, twill weave and dutch weave.

Wire diameter: 0.0018" – 0.0280".

Mesh size: 8 mesh – 200 mesh.

Width: 36", 48".

Length: customized.

Type | Ni + Co | Cu | Si | Mn | C | Mg | S | Fe | Impurity Sum |

Min. | Max. | ||||||||

N2 | 99.98 | 0.001 | 0.003 | 0.002 | 0.005 | 0.003 | 0.001 | 0.007 | 0.02 |

N4 | 99.9 | 0.015 | 0.03 | 0.002 | 0.01 | 0.01 | 0.001 | 0.04 | 0.1 |

N6 | 99.5 | 0.03 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.1 | 0.5 |

N8 | 99 | 0.15 | 0.15 | 0.2 | 0.2 | 0.1 | 0.015 | 0.3 | 1 |

Mesh count | Wire Diameter (in.) | Type Weave | Width Opening (in.) | Open Area (%) |

8 × 8 | 0.028 | Plain | 0.097 | 60.2 |

10 × 10 | 0.02 | Plain | 0.08 | 64% |

12 × 12 | 0.014 | Plain | 0.0693 | 69.2 |

16 × 16 | 0.012 | Plain | 0.0505 | 65.3 |

16 × 16 | 0.014 | Plain | 0.0485 | 60.2 |

20 × 20 | 0.0045 | Plain | 0.0455 | 82.8 |

20 × 20 | 0.007 | Plain | 0.043 | 74 |

20 × 20 | 0.014 | Plain | 0.036 | 51.8 |

25 × 25 | 0.006 | Plain | 0.019 | 57.8 |

26 × 26 | 0.01 | Plain | 0.0285 | 54.8 |

30 × 30 | 0.013 | Plain | 0.0203 | 37.2 |

40 × 40 | 0.006 | Plain | 0.019 | 57.8 |

40 × 40 | 0.01 | Plain | 0.015 | 36 |

50 × 50 | 0.002 | Plain | 0.018 | 81 |

60 × 60 | 0.007 | Plain | 0.0097 | 33.6 |

60 × 60 | 0.0105 | Twill | 0.0062 | 13.7 |

60 × 60 | 0.01 | Twill | 0.0057 | 11.6 |

70 × 70 | 0.004 | Plain | 0.0103 | 51.8 |

70 × 70 | 0.0045 | Plain | 0.0098 | 46.9 |

70 × 70 | 0.008 | Twill | 0.0063 | 19.4 |

80 × 80 | 0.0055 | Twill | 0.007 | 31.4 |

85 × 70 | 0.006 | Plain | 0 | 28.4 |

100 × 100 | 0.002 | Plain | 0.008 | 64 |

100 × 100 | 0.004 | Plain | 0.006 | 36 |

100 × 100 | 0.0045 | Plain | 0.006 | 30.3 |

200 × 200 | 0.0018 | Plain | 0.0032 | 41 |

application area

1. Electrode materials for lithium batteries, nickel hydrogen batteries, fuel cells, etc

Nickel mesh is used as a current collector or carrier for supporting structures of positive and negative electrode materials.

Especially in hydrogen nickel batteries and fuel cells, the conductivity and corrosion resistance of nickel mesh are crucial.

2. Supercapacitors

Nickel mesh can serve as a supporting substrate for active materials, improving energy density and conductivity.

3. Catalyst carrier

Nickel has excellent catalytic performance, and nickel mesh is commonly used in industrial catalytic scenarios such as hydrogenation reactions.

4. Filtration and Separation

Nickel mesh is used for solid-liquid separation, gas filters, etc. in high temperature and strong acid-base environments.

5. Electromagnetic shielding materials

Nickel mesh shields electromagnetic interference (EMI) and is used for military communication, electronic equipment protective cases, etc.

6. Conductive mesh material

Used in components such as thin film electrodes, heating elements, sensors, etc

The Nickel Woven Wire Mesh is specially designed to meet the needs of industries requiring exceptional resistance to heat, corrosion, and chemical attacks. Made from high-purity nickel wire, this woven mesh exhibits outstanding durability and stability even in extreme environments, such as chemical processing, aerospace, and electronics manufacturing.

Nickel’s inherent corrosion resistance allows the mesh to withstand oxidizing and reducing environments, while its high melting point ensures performance under elevated temperatures. The precise weaving technique creates uniform mesh openings that provide efficient filtration and separation, essential for protecting sensitive equipment and ensuring process purity.

Commonly used in filters, catalysts, protective shields, and reinforcement layers, the Nickel Woven Wire Mesh offers excellent tensile strength and flexibility. It can be customized in various mesh counts and wire diameters to suit specific industrial requirements.

Additionally, nickel mesh is non-magnetic and has excellent electrical conductivity, which benefits specialized electronic and electrical applications. Its resistance to acid and alkaline corrosion makes it suitable for use in batteries and chemical reactors.

With consistent quality control and advanced manufacturing, our nickel woven wire mesh delivers reliable performance, durability, and versatility for a wide range of industrial applications.

Our Nickel Woven Wire Mesh is engineered for demanding industrial environments where resistance to corrosion, heat, and chemical exposure is crucial. Manufactured from premium nickel wire, this metal woven mesh exhibits superior strength and longevity, making it ideal for filtration, screening, and protective applications.

Nickel’s excellent corrosion resistance against acids, alkalis, and oxidizing agents enables this mesh to perform reliably in chemical plants, petrochemical refineries, and power generation facilities. It withstands temperatures up to 1,000°C, making it suitable for high-temperature filtration and heat shielding.

The mesh is woven with precision to ensure consistent aperture size and mechanical stability, providing effective particle retention and airflow in filtration systems. It is widely used as catalyst supports, electrode screens, and in battery separators due to its electrical conductivity and chemical stability.

Customizable in mesh size and wire thickness, our nickel woven wire mesh can be tailored to meet the specific needs of your industrial processes. Its non-magnetic nature also suits electronic and aerospace applications where magnetic interference must be minimized.

Backed by stringent quality assurance, this nickel woven wire mesh delivers excellent performance, durability, and resistance, helping industries optimize their filtration and protection systems in harsh environments.

Please leave us a message and we will get back to you shortly.